Tandem Tools

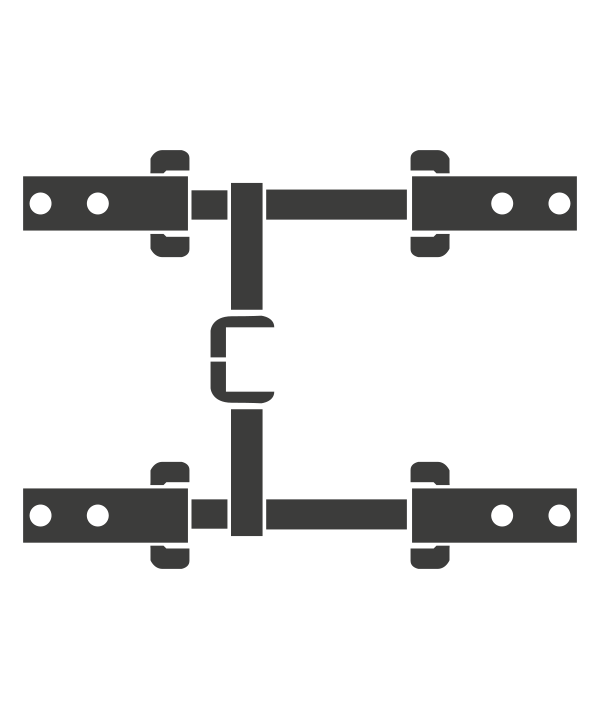

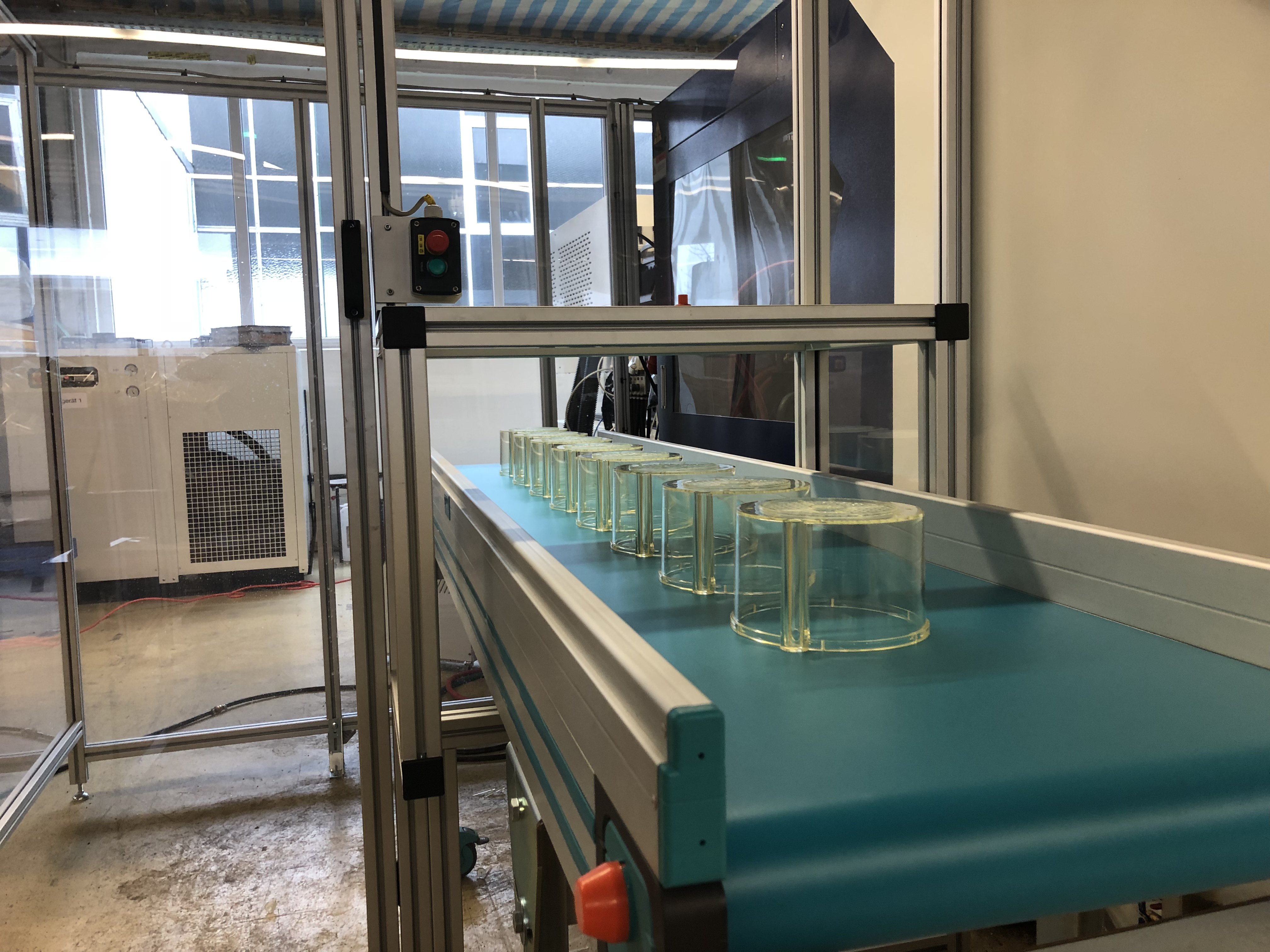

The functioning of a Tandem Tool can be explained simply, but the mechanism is elaborate.

In contrast to a normal injection mould tool, a Tandem Tool is equipped with two parting surfaces and, thus, is equipped with two cavities.

On the other hand the injection-mould machine does not need to have any special characteristics. The Tandem tool is steered by the software of the manufacturer’s injection-mould machine It controls the cycle in which a cavity is injected, during which the other cavity cools down.